- Home

- Products

- Packaging Equipment

- Plastic Bottle Mould

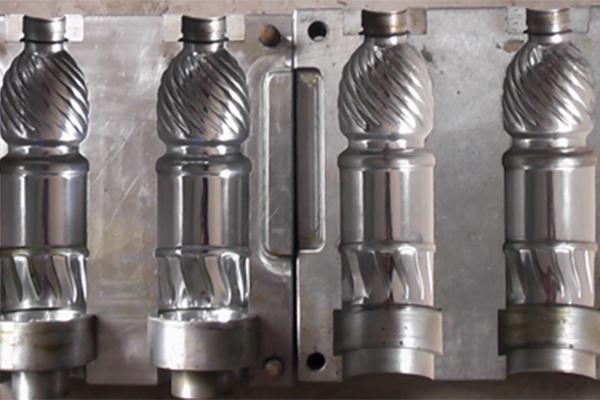

Plastic Bottle Mould

J&D Drinking Water Equipment Company is a specialized manufacturer of 48 cavities PET Preform Moulds injection and blow system with high technology. Our team is composed for senior engineers with master's degree and professional in 3D, we invite often technical committee members and senior professors in mould line as technical consultants for our company. Our production lines for plastic bottle mould have processing equipment and detection measurement instruments imported, as well as special drawing soft is applied in designing preforms, samples and manufacturing testing moulds. We supply special technology training and after-sales service to our clients.

Features of Plastic Bottle Mould

1. No cutting of valve gate is employed to reduce the labour cost.

2. Advanced hot runner system assures lower level of AA value.

3. Designed cold water channels increase cooling effect and shorten the cycle time.

Material of Plastic Bottle Mould

1. The main components of plastic bottle moulds are made of S136 material (Sweden ASSAB).

2. The mould base is made of imported P20. Plate method avoids corrosion and assures long life service of the plastic bottle moulds.

3. German vacuum stove is imported for heat treatments which assures the hardness of components HRC45-HRC48.

Inspection Method for Plastic Bottle Mould

1. Inspection tools include projector, hardness tester, stress tester, eccentric tester, electric balance and other inspection tools.

2. The screw neck is made and inspected strictly under Coca Cola standards.

After-Sales Service

Our professional team will perform after-sales service to assure stable operation of the plastic bottle mould machines.