- Home

- Products

- Packaging Equipment

- Bottle Blow Molding Machine

- Semi Auto Stretch Blow Molding Machine

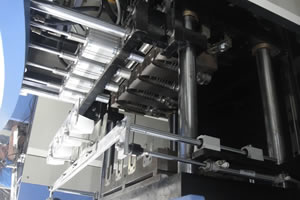

Semi Auto Stretch Blow Molding Machine

The JND series stretch blow molding machine is a semi-automatic unit built strictly to CE standards. By using microcomputer control system, operators are able to optimize molding parameters for high accuracy and stable quality. This stretch molding machine can be operated safely and effortlessly by only one person even without special training.

Perhaps the single most important product made by stretch blow molding is the PET bottle for carbonated soft drinks, though the process is also widely employed to make mineral water bottles, cosmetics bottles, and hot fill containers, especially oil bottles with handles.

Technical Parameters:| General Information | JND-SA4 |

| Clamping Force | 300KN |

| Number of Cavities | 4 |

| Theoretical Output | 0.5L:2000BPH |

| Mould Open Stroke | 380mm |

| Max. Mould Thickness | 190mm |

| Space Between Tie Bars | 670*500mm |

| Electrical System | |

| Voltage Standard | 380V/3PH/50HZ or special order |

| Total Power(Full Loaded) | 18kw |

| Container | |

| Max. Container Volume | 0.1-2.5L(4cav) |

| Max. Container Diameter | 110mm |

| Max. Container Height | 360mm |

| Auxiliary System | |

| Low Air compressor | 8-10Bar |

| High Air compressor | 30Bar |

| Dimension & Weight (L×W×H) | |

| Blow molding machine | 1900*880*1800mm |

| Preform Auto loader | 1900*660*1600mm |

| Net Weight | 1.3Ton |

Inquiry Form